Quick Email Now!

-

-

Phone Number

+86-318-7987220

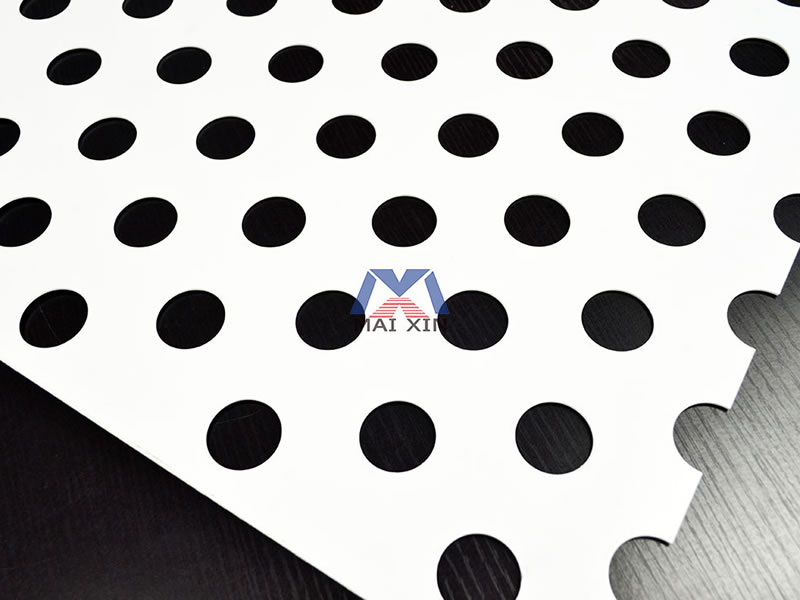

Perforated Metal Screen

Products

Perforated Metal Screen

Perforated Metal Plate

Perforated metal plate, also known as perforated sheet, perforated plate, or perforated screen. It’s a sheet metal that has been mechanically stamped or punched using CNC technology or in some cases laser cutting to create different holes sizes, shapes and patterns. It is widely utilized in structural, architectural, filtration and air movement applications. The perforated sheet Surface Treatment can be Spray, polishing, oxidation treatment, galvanized, powder coating, oil painting and etc.

Staggered 45°

Staggered 45° Staggered 60°

Staggered 60° Staggered

Staggered Straight

Straight Staggered

Staggered Straight

Straight

Plate | Thickness of | Hole | Pitch | Sheet | Sheet | Porosity | Weight |

Rolling | 0.2 | 6 | 2 | 1 | 20 | 44 | 0.88 |

0.35 | 5 | 4 | 1 | 20 | 24 | 2 | |

0.45 | 6 | 3 | 1 | 20 | 35 | 2.5 | |

0.8 | 3 | 3 | 1 | 20 | 19.6 | 3 | |

Flat plate | 0.5 | 1 | 1 | 1 | 2 | 19.6 | 3.14 |

0.55 | 1.1 | 2.2 | 1 | 2 | 22.67 | 3.411 | |

0.55 | 1.5 | 2.8 | 1 | 2 | 26.03 | 3.268 | |

0.8 | 1.5 | 1.5 | 1 | 2 | 19.6 | 5 | |

0.8 | 2.0 | 3.4 | 1 | 2 | 30.78 | 4.465 | |

1.5 | 2 | 2 | 1 | 2 | 19.6 | 9.4 | |

1.5 | 5.0 | 8.0 | 1 | 2 | 35.39 | 7.843 | |

3 | 5 | 16 | 1 | 2 | 19.6 | 18.8 | |

Stainless | 0.5 | 1 | 1 | 1 | 2 | 19.6 | 3.14 |

0.8 | 1.5 | 1.5 | 1 | 2 | 19.6 | 5 | |

1 | 2 | 2 | 1 | 2 | 19.6 | 6.28 | |

2 | 5 | 16 | 1 | 2 | 19.6 | 6.28 | |

Aluminum | 0.5 | 1 | 1 | 1 | 2 | 19.6 | 1.08 |

0.8 | 3 | 3 | 1 | 2 | 19.6 | 1.72 | |

1.6 | 2 | 2 | 1 | 2 | 19.6 | 3.24 | |

3 | 4 | 16 | 1 | 2 | 19.6 | 4.23 | |

Material | Low carbon steel, stainless steel, copper, nickel, Al alloy plate, Plastic plate, etc. | ||||||

Characteristics | |||||||

Use | Metope adornment, wind protection and dust suppression, medicine, filter, indoor noise, silencers and grain storage ventilation, etc. | ||||||